After all, high power network Optical fiber Laser in the whole set of equipment in the cost ratio is the highest, so many customers will bear the brunt of understanding the different between the laser configuration, performance, reliability, customer service and other differences. We do some simple data, we hope to have more systematic understanding of fiber lasers, help correct selection of terminal customers.

The characteristics of fiber laser are excellent, the terminal customers more and more in metal processing, consider using fiber laser scheme to replace the original processing method. With high power fiber laser localization, all the core device cost is large range So the selection threshold reduced, high power laser began to disappear.

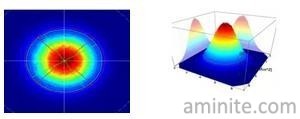

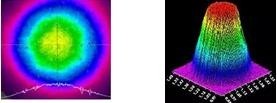

Comparison of single-mode and multimode beam quality

In cutting applications, the focal spot has a great influence on the quality of cutting out the core single-mode laser beam quality is better than the relatively small, multi-mode, energy distribution is Gauss distribution, among the highest energy density, three-dimensional map is a sharp peaks.

The core of multimode lasers compared to rough, poor beam quality compared to single-mode, single-mode spot energy distribution compared to the average number of 3D images, an inverted cup, from the edge of a steep, steep lot than the single mode multimode.

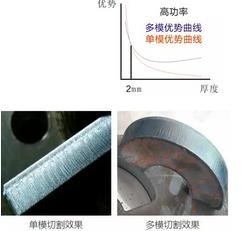

Multimode laser contrast with the power of the 1.5KW and 1.5KW mode

1mm sheet cutting speed is 20% higher than single mode multimode, visual effect is the same, but since 2mm, the speed advantage decreased gradually, starting from 3mm, the speed and effect of high power multimode laser speed and the effect of the advantage is very obvious, as shown below:

So the advantage in the single-mode multimode sheet, advantages in plate, single-mode and multimode and no comparable value, is a configuration of fiber lasers, like a car, the car for the road, off-road for mountain, but the car can run cross-country mountain, also can run the road, so in the selection of fiber laser multimode or single-mode to see the actual needs of the customer terminal processing.

How to choose the single mode and multimode

Distinguish from the power level, laser less than 1000W because the energy is not high, the main processing bias in the sheet material thickness, so the laser within 1KW using single mode configuration compared with the actual market situation, the laser power to Bohou both above 1KW. From the perspective of the processing industry, to enhance the quality of processing is a rigid demand, is not compromised, so a lot of high power laser selection will not consider the single mode, must guarantee the processing quality as the first!

At the same time, core single-mode generally smaller, which means the same power in the laser transmission, single-mode fiber core light energy carrying more, is a test of the material, at the same time when cutting high anti material, high intensity of reflected light and laser radiation superposition, if the fiber material will be very lack of tolerance to "burn core", while the core material life is also a challenge! So many laser manufacturers in high power fiber laser configuration still choose multimode configuration!

![]()

The single-mode fiber core is fine, bearing high laser energy

![]()

Multimode fiber core diameter, bearing laser capacity, long service life